PERMANENT REPAIR OF BROKEN CYLINDER BLOCK OF SHIP'S DIESEL GENERATOR - „DAIHATSU” BY TECHNOLOGY OF LOCK-N-STITCH AND WENCON PRODUCTS

ÂÚÇÑÒÀÍÎÂßÂÀÍÅ ÍÀ Ñ×ÓÏÅÍ ÖÈËÈÍÄÐΠÁËÎÊ ÍÀ ÊÎÐÀÁÅÍ ÄÈÇÅËÃÅÍÅÐÀÒÎÐ - „DAIHATSU” ÏÎ ÒÅÕÍÎËÎÃÈßÒÀ ÍÀ “LOCK-N-STITCH” È Ñ ÏÐÎÄÓÊÒÈ ÍÀ WENCON

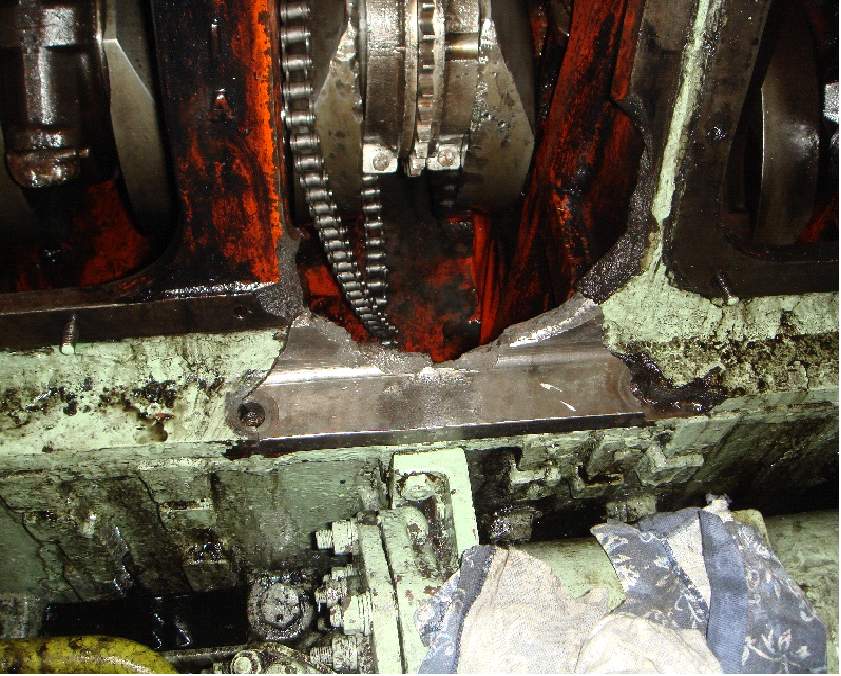

It was found the following damage caused by connecting rod :

- lower part of a crankcase opening was broken in 5 pieces

- on the upper part of the same opening was found 3 cracks

- Lower part repair:

Lower part of a crankcase opening was broken in 5 pieces

Lower two parts was stitched with C - stitching pins(cold weld) and tested on place

The upper three parts was stitched with C - stitching pins(cold weld) and was fixed to the lower two parts with Wencon Putty on place to the right angle

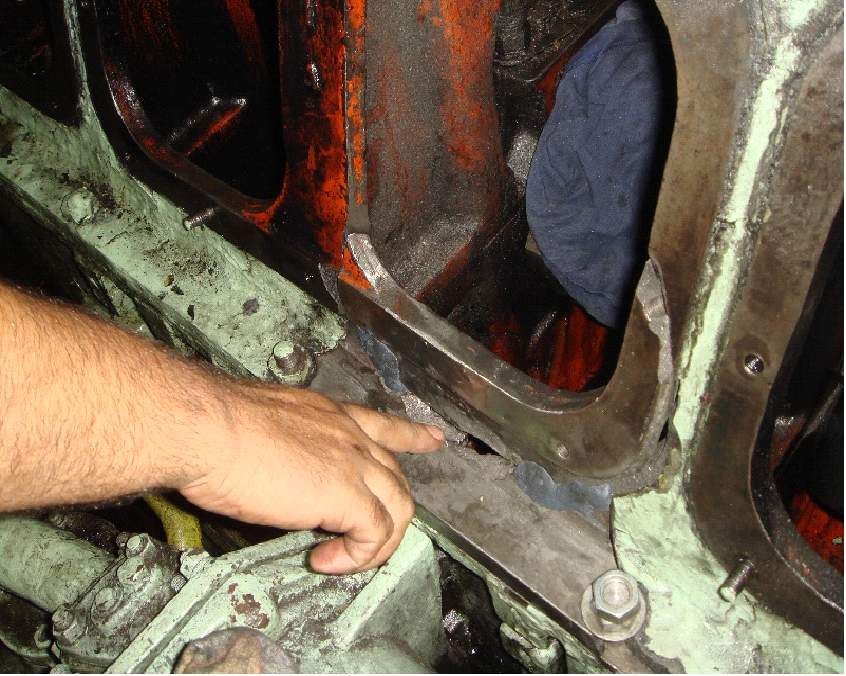

The upper three parts was stitched to the lower two parts with C - stitching pins

The part was fixed on place with Wencon Rapid

It was stitched on place with C - stitching pins(cold weld)

2.Upper part repair

It was found three cracks and was stitched with C - stitching pins

Rough sealing surface was filled with Wencon Rapid and after curing was ground with sand paper.